The main component of diamond-like carbon (DLC) coating is carbon. It is an amorphous hard film with high hardness and excellent friction properties. It is composed of graphite (SP2) and diamond (SP3). Because of its excellent friction performance, it is widely used in industry. Especially when there is no lubricant, the friction coefficient is also very low (μ = 0.005 ~ 0.2).

Diamond like carbon (DLC) coating has low friction coefficient, good adhesion resistance, high hardness and excellent wear resistance.

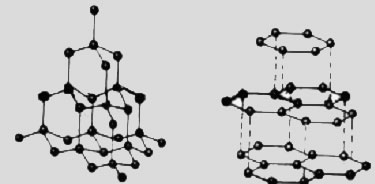

The carbon atoms of SP3 diamond form a continuous and solid skeleton structure in space, so it is hard and forms an octahedral lens.

The carbon atoms of SP2 graphite are in a planar layered structure, and the force between layers is small, so it is very soft, conductive and slippery.

DLC is a general term. The specific performance needs to be adjusted according to the actual situation, such as workpiece material, processing and use (friction symbol, speed, pressure and other parameters) to adjust the ratio of SP3 to SP2, so as to achieve the changes of thickness, wear resistance, hardness and other indicators, so as to adapt to the specific application occasion of the workpiece.

| Product | Cool SP series | Coating name | DLC diamond-like carbon | Coating color | Black gray |

| Characteristic | Wear resistance | Impact resistance | Corrosion resistance | High temperature resistance |

| Grade | Perfect | Perfect | Perfect | Commonly |

| Film thickness( μ m) | Maximum film hardness (hv0.05) | Standard friction coefficient for steel | Maximum applicable temperature (℃) | Coating structure |

| 0.5~10 | 2500 | 0.05~0.2 | 250 | Monolayer, composite, nano |